- Overview

- Summary

- Funding

- Cite This Publication

Overview

Who: Alexis Garrett, Arian Jaberi, Auston Viotto, Ruiguo Yang, Ali Tamayol, Ajay Malshe, Michael P. Sealy

Published: August 2, 2021

Where: International Solid Freeform Fabrication Symposium

Key Takeaway: A novel curing system that creates concentricly layered scaffolds can be used to produce scaffolds with similar mechanical properties to conventional meat.

Research Topics:

Summary

Alexis Garrett et al. test the impact of a novel curing system on the structure and efficacy of gelatin-based cultured meat scaffolds. A digital light processing (DLP) printer with a rotational collector plate is adapted to allow the scaffold to be cured radially, yielding concentric layers of scaffold material. Garrett et al. prepare gelatin methacrolyl scaffolds using the DLP printer and perform compression tests on them. These results are compared to compression tests performed on conventional sirloin steak, and it is found the mechanical properties of both the scaffold and the steak are similar. Garrett et al. argue this curing system holds potential in cultured meat production, especially in texture and mouthfeel recreation.

Written by Morgan Ziegelski

Cite This Publication

Garrett, A., Jaberi, A., Viotto, A., Yang, R., Tamayol, A., Malshe, A., & Sealy, M. P. (2021). Rotational Digital Light Processing for Edible Scaffold Fabrication. In 2021 International Solid Freeform Fabrication Symposium. University of Texas at Austin.

You Might Also Like...

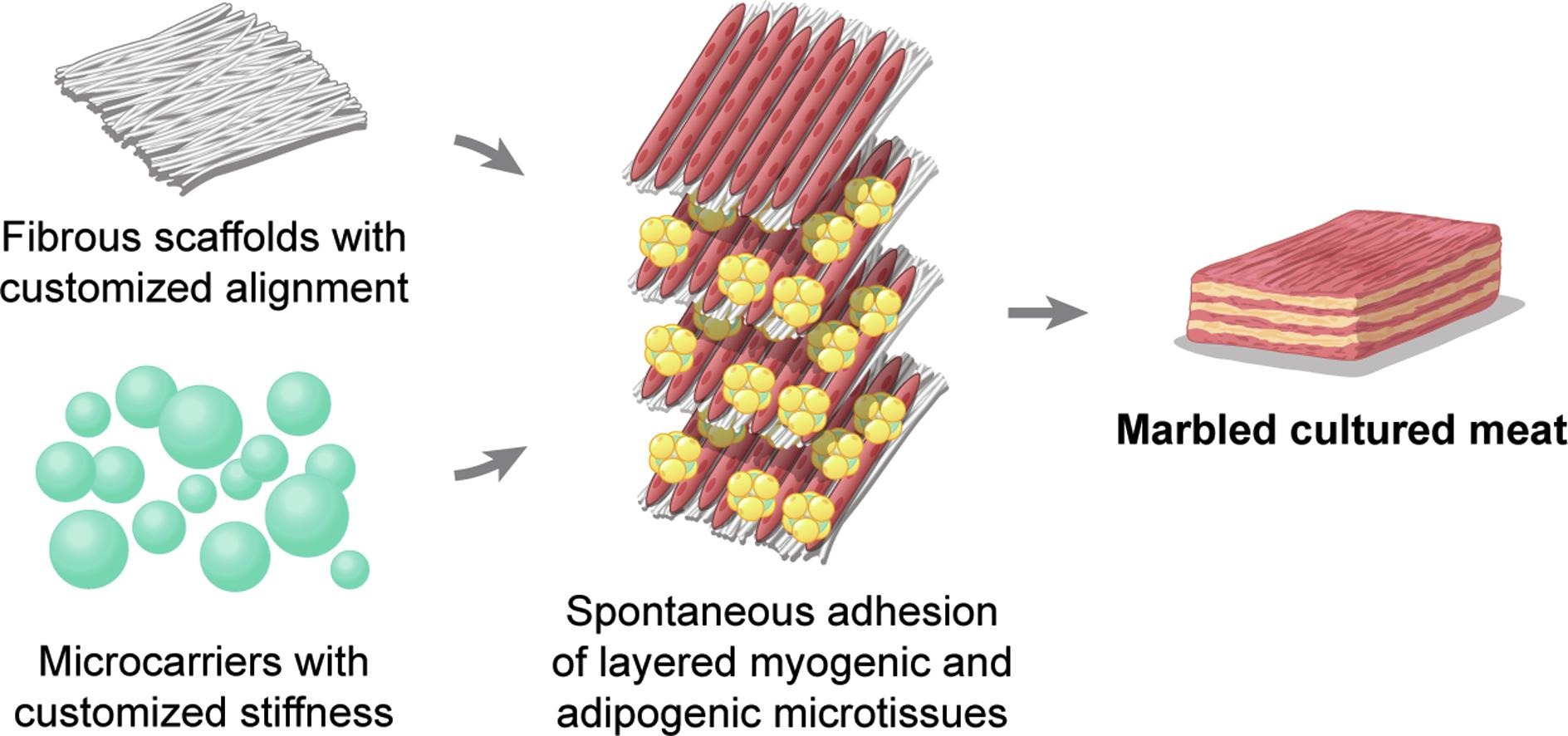

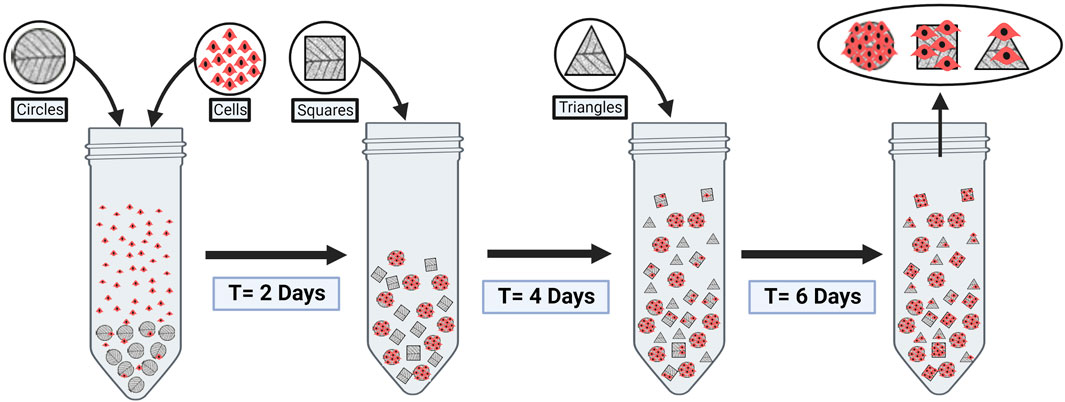

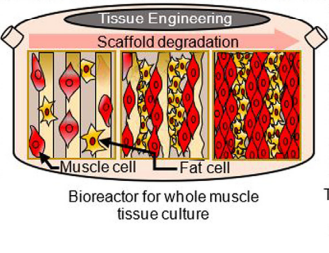

Engineering multicomponent tissue by spontaneous adhesion of myogenic and adipogenic microtissues cultured with customized scaffolds

N. Stephanie Kawecki, Sam C.P. Norris, Yixuan Xu, Yifan Wu, Ashton R. Davis, Ester Fridman, Kathleen K. Chen, Rachelle H. Crosbie, Andrea J. Garmyn, Song Li, Thomas G. Mason, Amy C. Rowat

Repurposing agricultural waste as low-cost cultured meat scaffolds

Luke R. Perreault, Richard Thyden, Jack Kloster, Jordan D. Jones, Jordan Nunes, Andriana A. Patmanidis, David Reddig, Tanja Dominko, Glenn R. Gaudette

Enzymatic degradation and ageing of additively manufactured soy-based scaffolds for cell-cultured meat

A. Garrett, K.L.M. Avegnon, L. Delbreilh, J. Segurola, N. Delpouve, M.P. Sealy