Hybrid Bioprinting

Printing textured meat more efficiently

Alexis Garrett

University of Nebraska-Lincoln, United States

Alexis Garrett

University of Nebraska-Lincoln, United States

Who: Alexis Garrett, Ph.D. student in mechanical and materials engineering

When: 2020 – Present

Institutes: University of Nebraska-Lincoln, United States

Supervisors: Michael Sealy, assistant professor of mechanical and materials engineering at the University of Nebraska-Lincoln; Ali Tamayol, associate professor of biomedical engineering at the University of Connecticut; Laurent Delbreilh, Maitre de Conferences at the University of Rouen

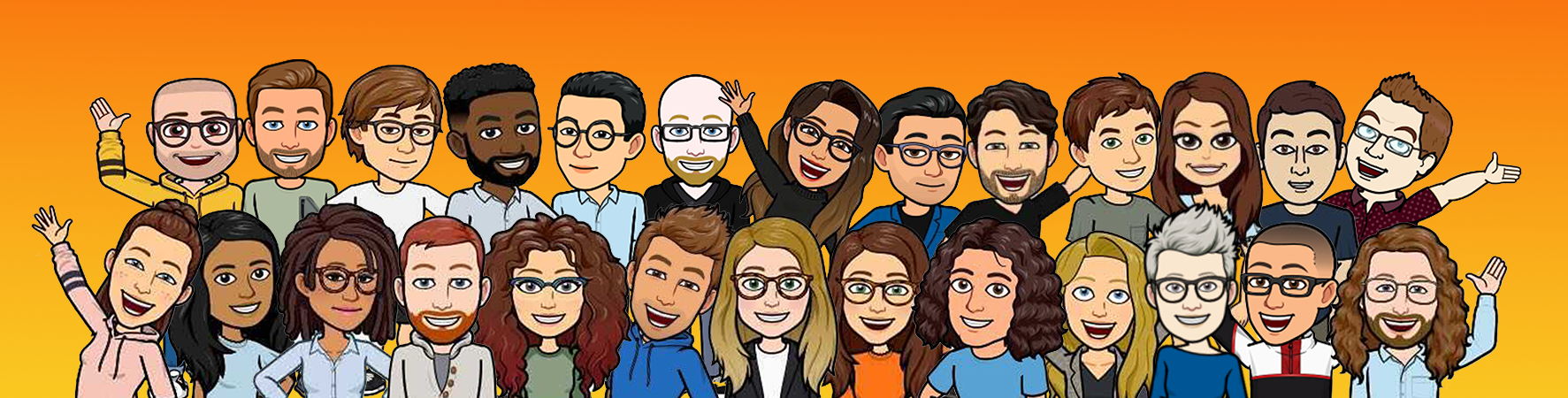

Alexis is combining two different methods to make a scaffold for cultured meat: stereolithography and electrospinning. Stereolithography is a form of 3D printing technology that uses light to build the material layer-by-layer. Electrospinning forms a bundle of fibers that are highly aligned, just like the muscle in meat. By combining these two methods, Alexis aims to make a scaffold that can be rapidly printed with the texture of meat.

Alexis’ hybrid approach will help to solve many of the issues with current manufacturing methods, which are slow, expensive, and fail to recreate the texture of anything other than ground meat. Stereolithography allows her to print meat more efficiently, while electrospinning helps create the texture of muscle.

Featured

December 2020

Announcing New Harvest’s 2020 Grantees, AnnouncementPublications

Rotational Digital Light Processing for Edible Scaffold Fabrication

International Solid Freeform Fabrication Symposium, 2022