by Donavyn Coffey

Cultured meat has come a long way since the first lab-grown burger made its world debut in 2013. Driven by dozens of start-ups all over the world, the price tag of meat without animals has decreased steadily, and its quality has significantly improved. The next frontier is consistency. Until recently, all of it was effectively ground meat — a sludge of cells that could be shaped into burgers, patties and nuggets. The challenge now is to produce a bigger, more substantial piece of flesh: a muscle, like a steak or a pork loin. This requires new technology.

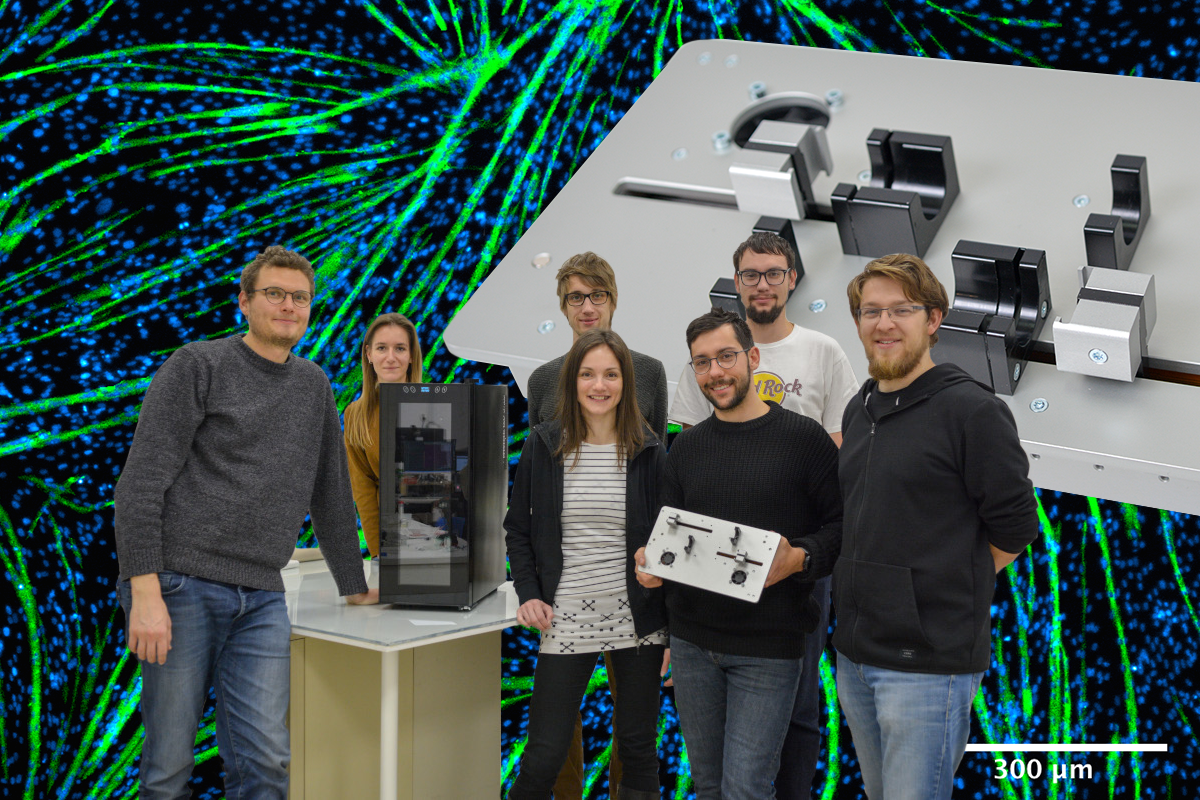

One promising effort in this pursuit is currently underway in Slovenia. The IRNAS Institute for Development of Advanced Applied Systems has been working on a new complex kind of bioreactor, which closely mimics the nutrient-distribution in an animal’s body, and is constantly updatable. Funded by New Harvest, and building on a prototype created by researchers in the US and Canada, this international cooperation may just bring us cultured meat 2.0.

AMBITIOUS DESIGNS

It started like so many New Harvest projects — with an ambitious research proposal. In 2017, Jessica Krieger, a New Harvest Research Fellow at Kent State University, proposed the creation of a perfusable bioreactor capable of growing an entire system of cells — a muscle — through electrical stimulation.

In an animal, veins distribute fresh oxygen and nutrients to the muscle, an extracellular matrix offers it structural support, and the heart keeps resources moving into the muscle and waste moving out. Without this system of distribution, the cells on the outside of the muscle consume all the nutrients and oxygen while the innermost cells are starved and stifled.

With her proposed bioreactor, Jess hoped to create a proxy for a body that eats and breathes, replicating the necessary conditions for cells to grow into tissue. She just needed someone to build it.

A group of undergraduate engineers at the University of British Columbia — Han Zhang, Yi-Fan Chen, and Kyle Manke — were prepared to do just that. For a capstone project, they wanted to design a bioreactor for cultured meat. Lacking experience in cell culture, they reached out to New Harvest for guidance.

New Harvest’s research director, Kate Krueger, realized that Jess, with her tissue engineering expertise, and the undergrads, with their hands-on experience with circuits, would make a perfect team. The only problem was that New Harvest didn’t have a mechanism to support such a circumscribed project. Knowing that the undergrads needed funding, Kate created the New Harvest Seed Grant program.

With New Harvest’s support, Han, Yi-Fan, and Kyle spent the next year working on a bioreactor prototype under Jess’s counsel.

The “undergraduates impressed us with how far they were able to get with Jess’s mentorship,” Kate Krueger says now. In mid-2018, with their prototype in hand, Krueger went looking for world experts in hardware to take the project to the next level.

She found what she needed in IRNAS, a Slovenian organization specializing in rapid development of hardware prototypes. The team of engineers build hardware with constant input from an array of biologists and research scientists. “The goal of our company is to put tech advances in the service of science,” says Luka Banovic, IRNAS engineer and manager on the bioreactor project. “Scientists tend to be really creative people. They present questions you would never think of.”

Working with an extensive team of experts, they have created a new bioreactor prototype for growing muscle. This latest iteration offers constant perfusion, meaning it constantly replenishes the nutrients on its own — mimicking the constant circulation in a body. Sponge-like structures, called scaffolds, support the muscle tissue as it grows, and allow nutrients and oxygen to diffuse down into the piece of meat so that all cells have adequate energy and oxygen. The bioreactor simulates the dynamic conditions of the body and requires far less labor than typical cell culture methods. Researchers can run longer, more realistic experiments.

EVOLVING HARDWARE

This summer, a prototype of the New Harvest-funded IRNAS bioreactor will be going to the University of Maribor for testing. The engineers at IRNAS lack tissue engineering experience, so graduate student Jernej Vajda will be working with the team under the supervision of Dr. Uro š Maver as a biological consultant to see how cells grow and survive in the prototype.

Because both IRNAS and the University of Maribor are in Slovenia, the prototype will be able to travel back and forth between the two institutions as Jernej tests each step and the IRNAS team makes changes in response.

One of the IRNAS team’s primary goals is to make the bioreactor easily updatable, adaptable to the constant flurry of new research coming out of the cellular agriculture field. “We see a trend where conventional lab methods aren’t enough for planned research,” said Bostjan Vihar, a biologist working on the bioreactor at Institute IRNAS. “No one knows what equipment you will need in a year, or two or five.”

Many researchers can’t conduct the most realistic or efficient experiments, Vihar says, because they don’t have the technology to support it. For that reason, IRNAs plans to collaborate with research groups to upgrade and adapt the hardware over time, tailoring the technology to the rapidly-evolving field. They hope this approach catches on.

SHARING THE SPOILS

New Harvest and IRNAS are both open source, and publish their findings and results as they go. Once the bioreactor prototype is tested, the schematics will be published online so others can build it or build on it. IRNAS documentation of the project is available on GitHub as well.

“As a donor-funded non-profit, it’s really important for us to do what we can to accelerate the entire field of cellular agriculture,” Krueger says. “It’s really hard to find groups in cellular agriculture that are willing to share data.”

As far as Krueger knows, no one else in cellular ag is working to optimize a bioreactor for muscle tissue growth. Vihar says that their hope is that, within five years, the bioreactor will be highly customizable, and ideally offer researchers a way to control all environmental parameters and measure the response in the tissue. This kind of control would speed up research trials immensely. It’s the kind of innovation that could help cultured meat make the transition from the lab to the market.

This article was produced for New Harvest by Massive Science, a community of scientists telling fascinating, true stories about the science that’s happening now.