We’re excited to share the designs for an open source bioreactor – a project six years in the making with many evolutions.

Back in 2017, New Harvest Research Fellow Jess Krieger pioneered a new project to build a cultured meat bioreactor with an ambitious team of mechanical and materials engineering students at the University of British Columbia: Han Zhang, Kyle Manke, and Yi-Fan Chen.

Their initial project, to design and build a scalable and modular bioreactor prototype for 3D cultured meat production, kicked off what became a six-year project to make an open source bioreactor that could be used by researchers and companies alike to advance cultured meat production.

After the students completed their prototype, New Harvest looked for a team who would upgrade the technical capacities of the bioreactor and test it on real use-cases for cellular agriculture. This pursuit led to a collaboration between interdisciplinary researchers at Institute for Development of Advanced Applied Systems (IRNAS Ltd.), a Slovenian organization specializing in rapid development of hardware prototypes with a focus on open.

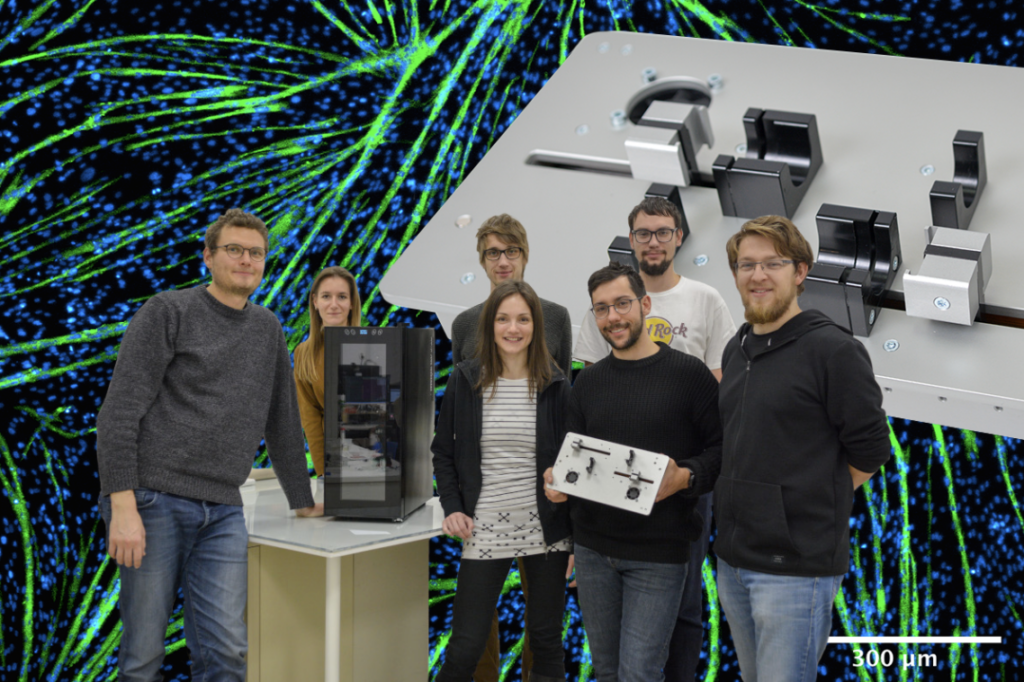

Some of the team at Institute for Development of Advanced Applied Systems (IRNAS Ltd.)

After many practical evolutions to the design, the collaboration culminated in a new and open-source, modular, perfusion-based bioreactor which would enable 3D tissue culture.

The research and development efforts revealed some important limitations as well as opportunities for further development of cell and tissue culture perfusion systems. This led to a continuation of the project and an extension of the project team by the Institute of Biomedical Sciences at the University of Maribor.

Over the last two years, the IRNAS and University of Maribor team developed a new piece of tech – a perfusion system that allows controlled supply of nutrients and removal of waste from engineered tissue constructs within commonly used laboratory cell culture incubators.

The design is now completed and published on Github under open-source licensing!

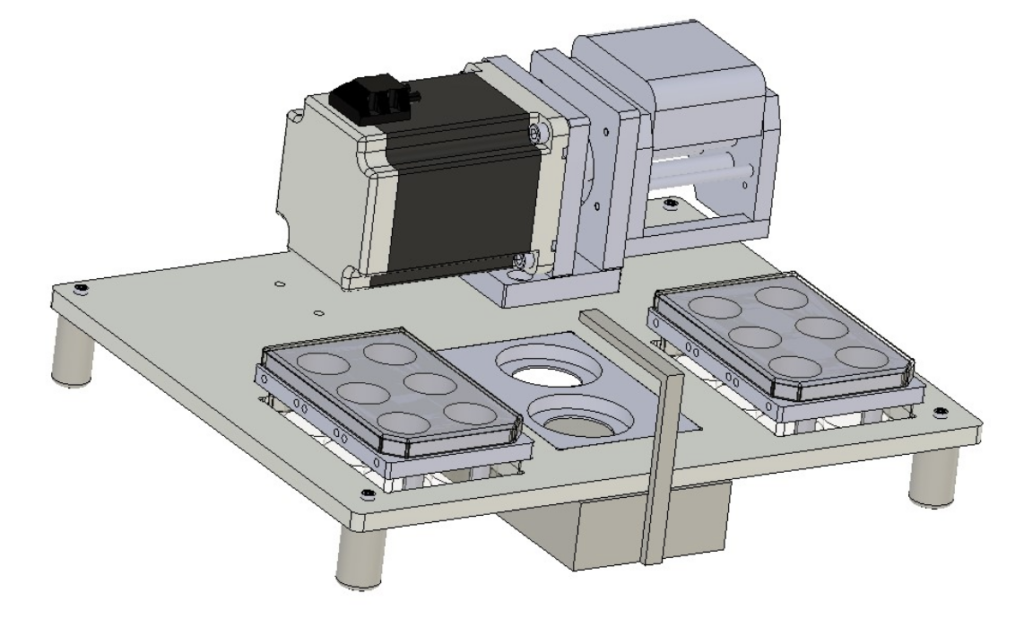

Illustration of the in-incubator perfusion system

You can find everything you need to build your own perfusion system here!

Unlike most bioreactors you hear about in cell ag – large tanks used to grow a large number of cells – this system is intended to grow a 3D tissue.

Whole tissues, like steak or pork chops, are a lot more challenging to keep alive than a slurry of cells. What is so important about this new system is that it provides programmable perfusion, mimicking the constant circulation of nutrients and oxygen provided by blood in a body, which is necessary to grow a 3D tissue. The perfusion system simplifies assembly of the perfusion set-up and transfer between the clean bench and the incubator, where it offers precise control over the flow-rate in up to eight parallel channels.

The system is intended to be updatable and adaptable, so it can grow with the rapidly evolving cultured meat space. For that reason, the updated design works within a standard cell-culture incubator, rather than as a standalone bioreactor.

Next, New Harvest Fellow Jernej Vajda at the University of Maribor will use the perfusion system to study the impact of shear stress in combination with other conditions for vascular tissue engineering, such as cells, media and scaffold characteristics.

We hope all of you can use the bioreactor for your own work!

***Here’s how you build the perfusion system***

Open-source licensing means the hardware, firmware, software and documentation can be used without paying a royalty. You can even make changes to customize the system for your own needs, but all future versions must reference the original design and also be shared under open-source licensing!

We encourage others to build the system themselves. Or, reach out to us if you would like to use it but don’t have the ability to manufacture one yourself.

If you try it out, please let us know how it goes! The more we work on these tools together, the better they become.

Happy Open Access Week!